An industrial heating element is an electric component designed to convert electrical energy into heat for industrial applications such as pipeline heating, machinery warming, and temperature control in manufacturing processes.

Industrial Heating Element is a reliable, high-performance electric heating solution designed for a wide range of industrial applications. Made from premium materials and engineered for durability, this Industrial Heating Element provides efficient, uniform heat output suitable for pipelines, containers, machinery, and precision instruments.

High-Quality Electric Heating Element

Manufactured using advanced resistance wire technology to ensure long-lasting performance and stable heat output.

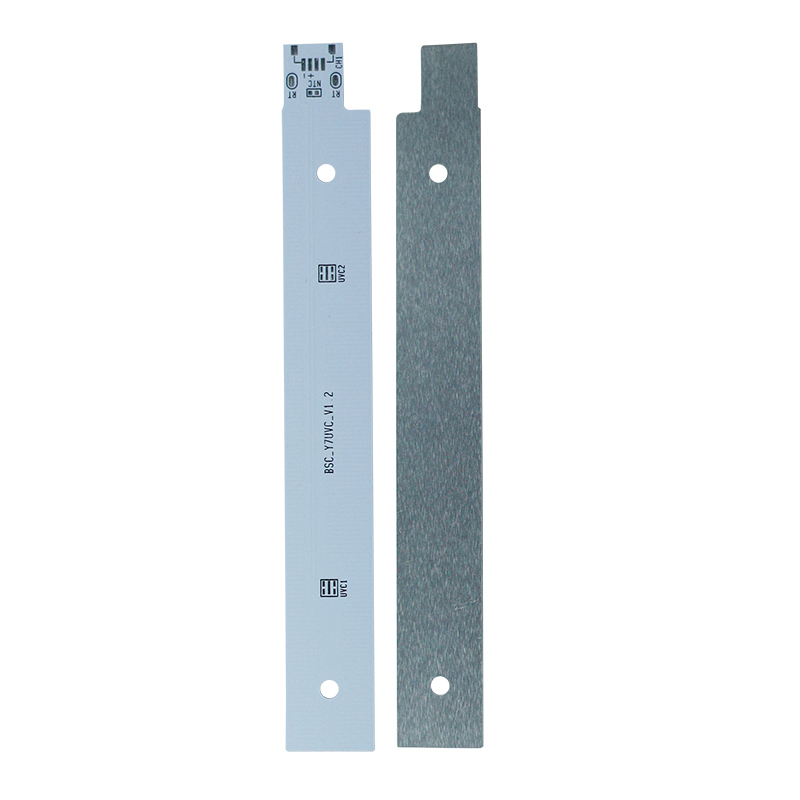

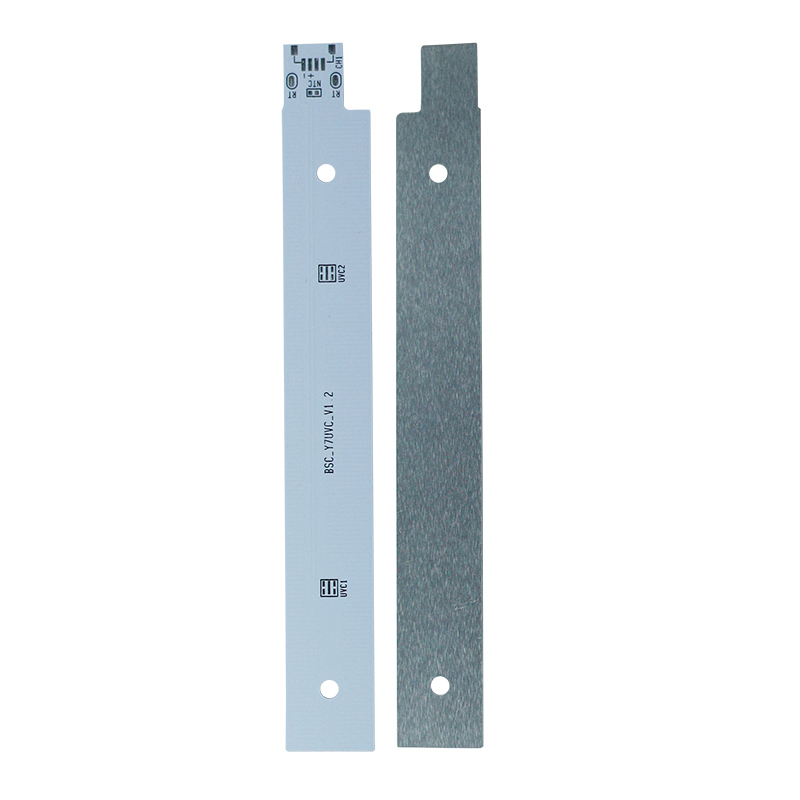

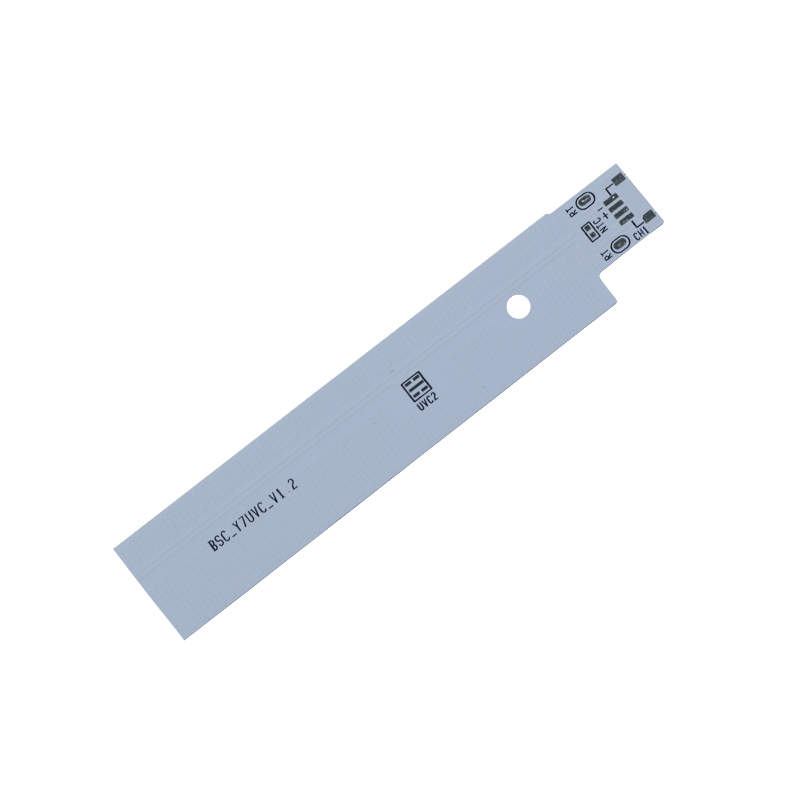

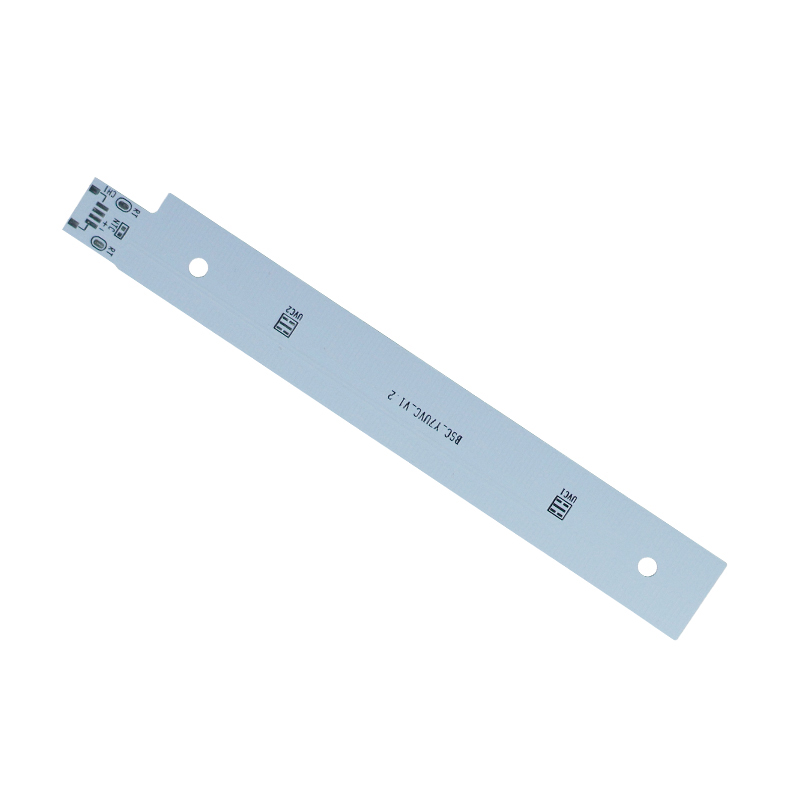

Flexible Heating Element Designs

Available in various shapes including tapes, cables, and coils to fit diverse industrial heating needs.

Temperature Controlled Heating Element

Compatible with thermostats and temperature controllers for precise temperature management.

Durable and Waterproof Heating Element

Constructed to withstand harsh industrial environments with excellent resistance to moisture and dust.

Energy Efficient Industrial Heating Element

Designed to deliver optimal heating while minimizing energy consumption.

Quick Response Flexible Heating Element

Low thermal mass allows rapid heat-up, improving operational efficiency.

| Parameter | Specification Range |

|---|---|

| Voltage | 110V, 220V, 240V (custom options available) |

| Power | 10W to 1500W (based on application) |

| Temperature Range | -60°C to +300°C (depending on material) |

| Shape | Tape, cable, coil, or custom forms |

| Insulation Material | Silicone, fiberglass, or specialized coatings |

The industrial heating element operates by passing electric current through a high-resistance wire, generating heat. This heat is transferred evenly to the surrounding area or surface through insulating materials like silicone or fiberglass. Temperature controllers can regulate the element to maintain precise and stable heating, suitable for industrial process control and equipment maintenance.

Pipeline and Container Heating

Prevent freezing and maintain viscosity of fluids in chemical, petroleum, and food industries.

Machinery and Equipment Heating

Provide stable heat to motors, pumps, valves, and other industrial machinery components.

Laboratory and Scientific Equipment

Enable precise temperature control for experimental setups and analytical instruments.

Electronics and Medical Device Heating

Maintain optimal operational temperatures for sensitive electronics and medical instruments.

Automotive and Aerospace Applications

Used for antifreeze heating and environmental temperature control in extreme conditions.

Installation: Select the appropriate heating element shape and size, then securely attach it to the heating surface using suitable adhesives or mechanical fasteners.

Power Connection: Connect the element to the correct voltage supply and ensure proper wiring safety standards.

Temperature Control: Use compatible thermostats or controllers for accurate temperature regulation.

Safety Checks: Regularly inspect connections and insulation for wear or damage before operation.

Efficient Heat Transfer

Close contact with surfaces ensures maximum heat conduction and energy savings.

Versatile and Customizable

Available in various forms and sizes to meet specific industrial heating demands.

Robust and Long-Lasting

Built to withstand extreme temperature and environmental conditions, reducing downtime.

Low Maintenance and Cost-Effective

Durable materials minimize replacement frequency and reduce operational costs.

Q1: What is an Industrial Heating Element?

An industrial heating element is an electric component designed to convert electrical energy into heat for industrial applications such as pipeline heating, machinery warming, and temperature control in manufacturing processes.

Q2: What types of Industrial Heating Elements are available?

Common types include flexible heating tapes, heating cables, resistance wire coils, and custom-shaped heating elements made from materials like silicone or fiberglass insulation.

Q3: What temperature range can Industrial Heating Elements operate in?

Most industrial heating elements operate safely within a temperature range of -60°C to +300°C, depending on the design and insulation materials used.

Q4: How do I choose the right power and voltage for my Industrial Heating Element?

Power and voltage depend on your application requirements. Standard options typically include 110V, 220V, and 240V with power ranging from 10W up to 1500W. Custom specifications are also available based on your needs.

Q5: Can Industrial Heating Elements be used in wet or dusty environments?

Yes, many industrial heating elements come with waterproof and dustproof insulation such as silicone, rated at IPX6 or higher, suitable for harsh industrial conditions.

Q6: How do I control the temperature of the Industrial Heating Element?

Industrial heating elements can be paired with thermostats or temperature controllers for precise temperature regulation and energy efficiency.

Previous: Seedling Mat

Next: Heating Film

Contact

No. 1, 1st Road, Mawu Industrial Zone, Qiaoli, Changping Town, Dongguan City, Guangdong Province

Email:

Phone:

+86 136-2001-9955

+86-0769-83488762-8016