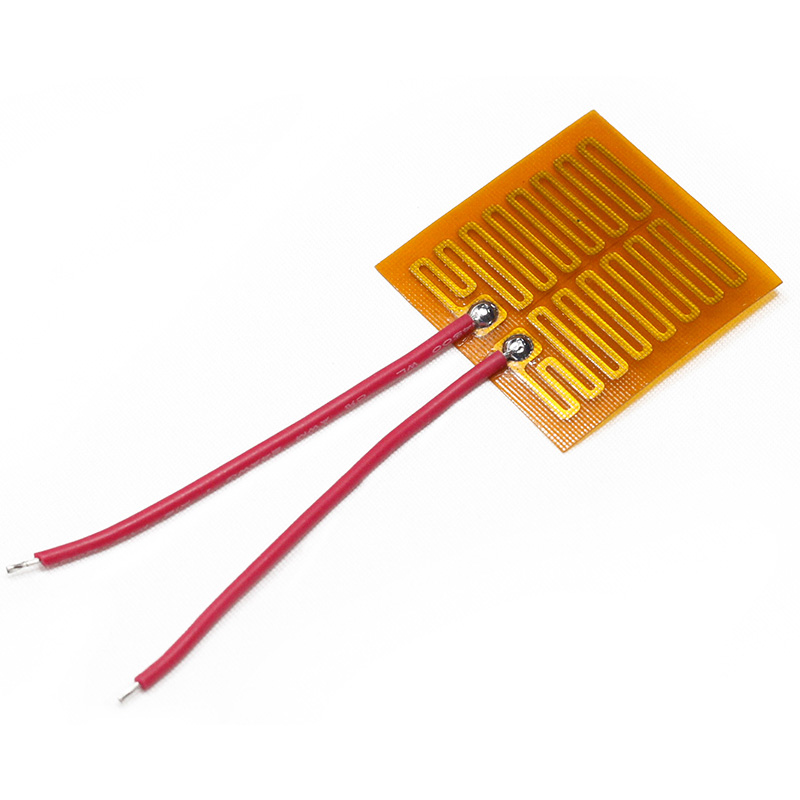

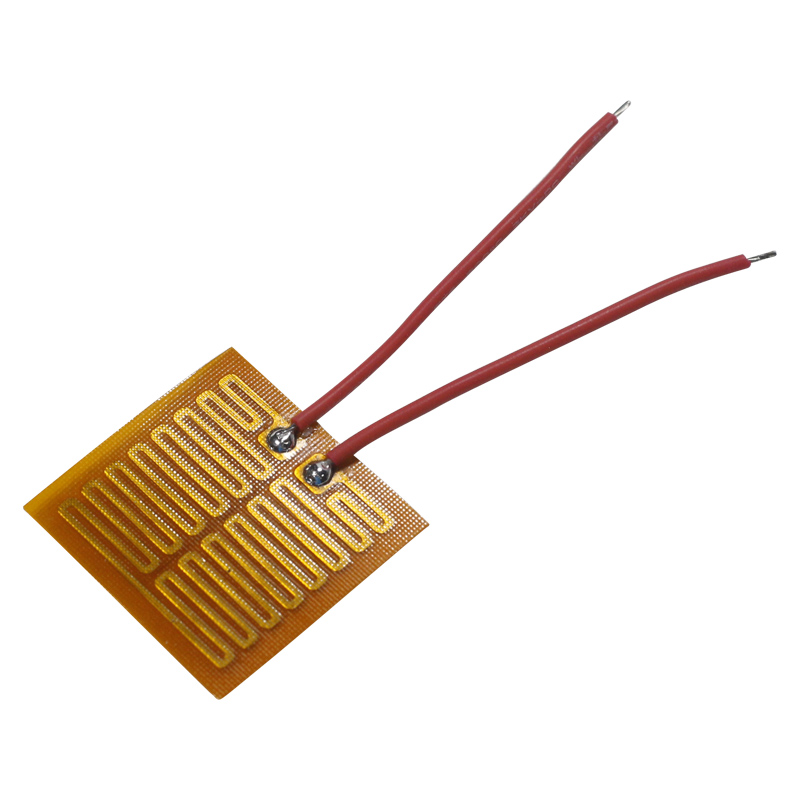

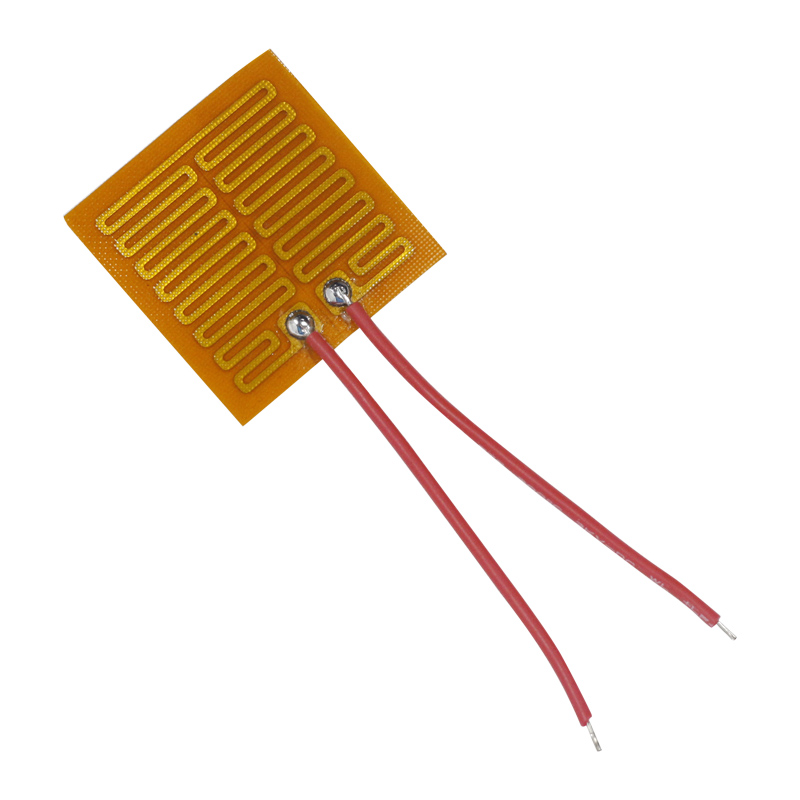

The polyimide film heater is a highly reliable and flexible heating solution, and its thin and robust construction makes it ideal for use in a variety of scenarios where precision heating is required. Its ultra-thin design, efficient heating, high temperature and chemical resistance make it widely used in aerospace, medical, electronics, automotive and other applications. By being customized to meet customer needs, polyimide heaters are able to provide optimal heating solutions for a wide range of application scenarios.

Polyimide Film Heater is an ultra-thin flexible heating device consisting of a polyimide film as an insulating layer and an embedded resistance circuit. Polyimide materials are known for their excellent resistance to high temperatures, chemicals, and excellent electrical insulation properties, and are therefore widely used in scenarios that require precise heating, fast response, and tight space requirements. Polyimide film heaters are ideal for complex heating needs due to their extremely thin thickness and flexibility, allowing them to fit well on a variety of shaped surfaces.

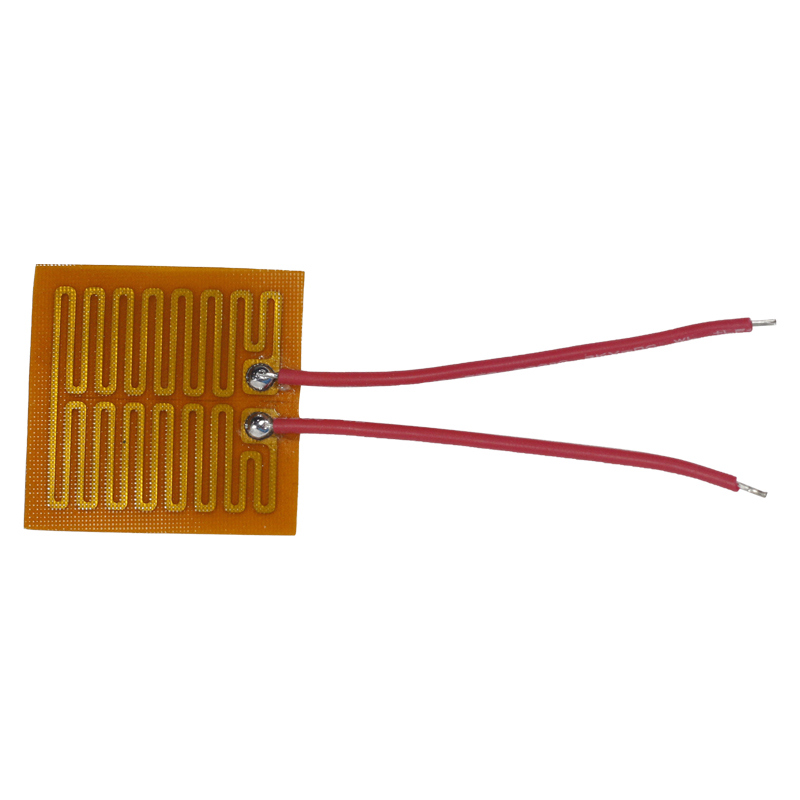

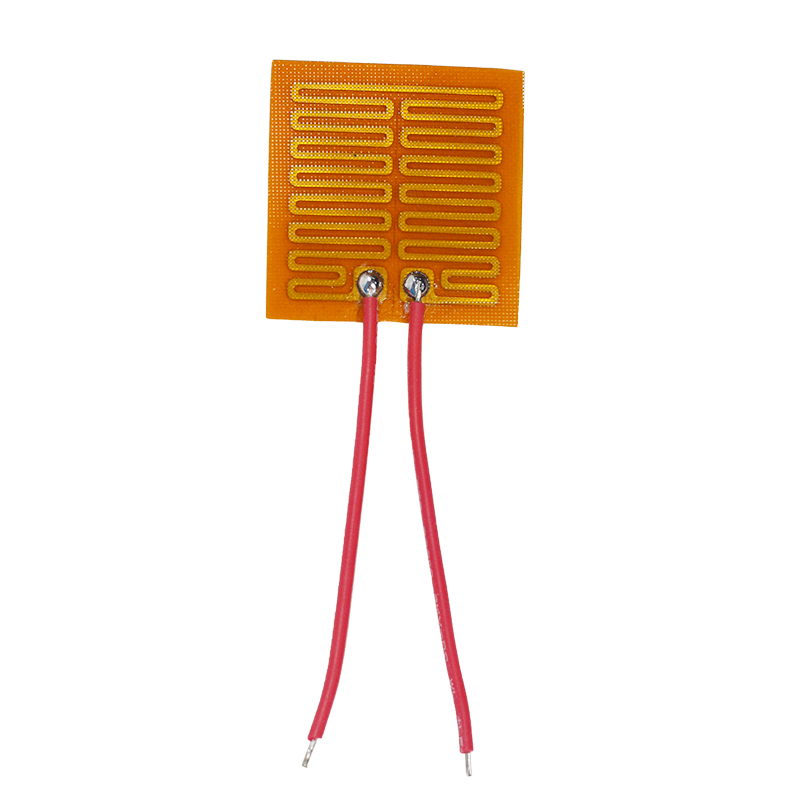

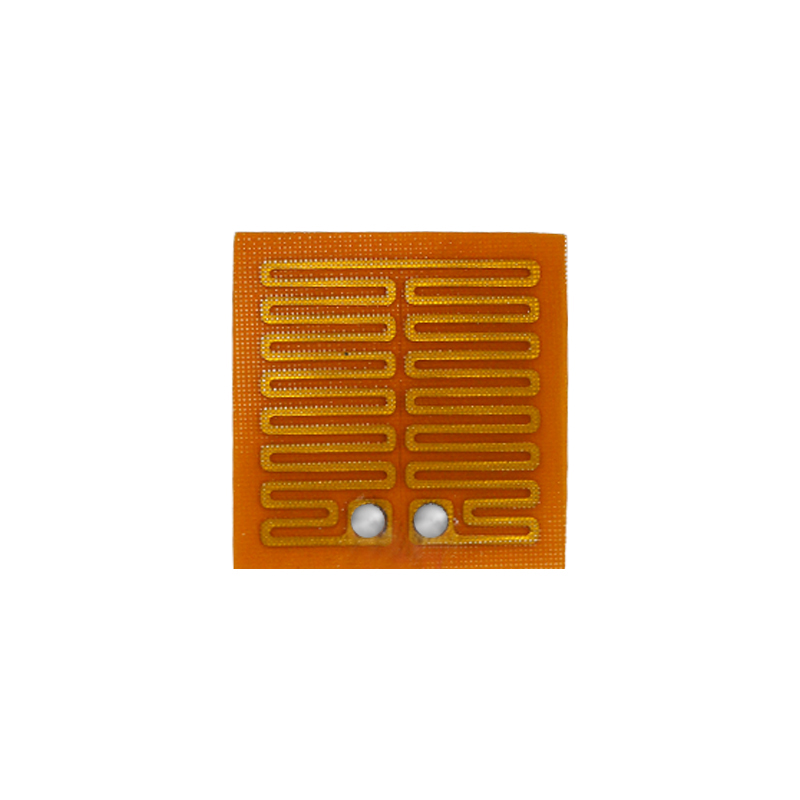

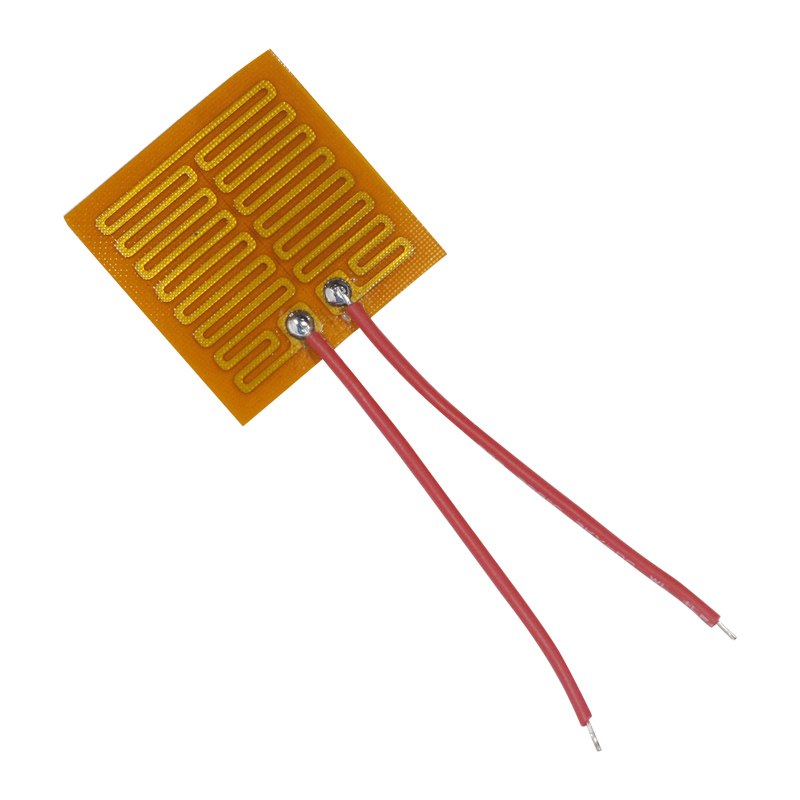

Product Construction

The main structure of the polyimide film heater includes:

1. Polyimide film (outer layer): used as an insulating and protective layer, it has excellent mechanical strength and thermal stability, and can withstand a very wide range of temperatures, usually working stably in the range of -269°C to 260°C.

2. Etched Metal Circuitry: Nichrome resistance circuitry is embedded in polyimide film through etching technology. The circuitry is extremely thin (usually only 0.1mm) and provides uniform heating.

3. Adhesive layer: Some models have a self-adhesive layer on the back of the heater, which makes it easy to mount quickly and securely to a variety of surfaces and adapt to different application scenarios.

4. Ultra-thin design: The thickness of polyimide film heaters is usually between 0.1mm and 0.3mm, which is extremely thin and light, and can be easily installed in small spaces and complex shapes of equipment.

5. Excellent temperature range: it can work at very low temperatures (e.g. -269°C), which is suitable for extreme environments, and it has outstanding high-temperature resistance, and its performance remains stable at 260°C.

6. Efficient and uniform heating: with etched circuit technology, the resistance circuit can be uniformly distributed in the heating area to ensure no local overheating phenomenon and realize precise temperature control.

7. Strong flexibility: Due to the soft characteristics of polyimide material, the heater can be tightly adhered to irregularly shaped surfaces to ensure the uniformity of the heating effect.

8. Fast warming: polyimide film heater has a very fast warming speed, can reach the target temperature in a short time, reduce energy consumption and improve work efficiency.

9. Chemical resistance: polyimide materials have excellent corrosion resistance to many chemicals, solvents and grease, suitable for long-term use in harsh chemical environments.

10. Excellent electrical insulation: Polyimide's insulation performance is extremely high, withstanding voltage up to 5000V or more, to ensure electrical safety in the process of use.

Application Fields

1. Aerospace equipment: polyimide film heaters are widely used in temperature control systems in aerospace vehicles, such as satellites and spacecraft in the heating of electronic equipment, to ensure the normal operation of equipment in extreme environments.

2. Medical equipment: Used for heating and temperature control of medical equipment, especially equipment that requires high precision, low thermal inertia and space constraints, such as patient care equipment and laboratory instruments.

3. Electronic equipment heating: applied to electronic components, displays and sensors that require precise temperature control to prevent functional failure in cold environments.

4. Automotive industry: Widely used in electric vehicles for battery preheating, mirror defrost heating, seat heating, etc., to help the vehicle in the low-temperature environment to quickly start and maintain the best operating conditions.

5. Communication equipment: used in communication equipment to keep the temperature of antennas, receivers and other sensitive electronic components constant, to ensure stable operation of the equipment in various climatic conditions.

6. Industrial equipment: Polyimide heaters are used for heating and insulation of pipelines, liquid storage tanks, or for heating and temperature control inside equipment to ensure efficient operation in harsh industrial environments.

Customization Options

1. Shape and size: Any size and shape, such as round, square or shaped, can be customized according to specific equipment or application requirements for optimal installation and heating.

2. Voltage and power density: Voltage and power density adapted to different working conditions can be customized according to the requirements of different application scenarios to achieve high efficiency and economy of the heater.

3. Temperature control system integration: thermocouples, temperature sensors, etc. can be integrated into the heater to ensure accurate monitoring and control of the temperature to meet the demand for precise heating.

4. Adhesive backing option: Optional heaters with adhesive backing are available for quick and secure mounting to heated surfaces.

5. Wiring options: Different wiring interfaces or lead lengths can be customized for easy integration and installation with the system.

Packaging and Transportation

Polyimide film heaters are usually packed in anti-static bags to avoid static damage during transportation. Anti-vibration foam or other protective materials are also added to ensure that the product will not be damaged during transportation. Each product is thoroughly quality checked before shipment to ensure its stable performance.

| Dielectric strength | UDC 500V ≥ 200MΩ |

| Electrical resistance | UAC ≥ 2000 V |

| Operating temperature | Long-term use ≤ 232 ℃ |

| Weight | ≤ 278 g/m² |

| Heat flow density (without heat sink and temperature control) | ≤ 1.1W/cm² |

| Heat flow density (with heat sink and temperature control) | ≤ 6.5W/cm² |

| Thickness | ≤ 0.20 mm |

| Power | Variable according to the specific application, need to provide electrical parameters such as voltage, resistance, etc. |

| Outside lead position | According to specific design |

| Direction of outer lead | According to specific design |

| Outer lead length | According to specific design |

| Thermal conductivity | Excellent |

| Resistance stability | Excellent |

What is a polyimide film heater?

A polyimide film heater is an ultra-thin flexible heater that utilizes polyimide as the external insulating material with an embedded etched metal resistance circuit. It has high heat resistance and electrical insulation properties, and is widely used for precise temperature control and space-constrained scenarios.

What is the operating temperature range of polyimide film heaters?

Polyimide film heaters typically have an operating temperature range of -269°C to 260°C and are capable of maintaining stable performance in extreme low and high temperature environments.

What are the key benefits of polyimide film heaters?

Key benefits include ultra-thin design, fast temperature rise, excellent electrical insulation, high flexibility, high temperature and chemical resistance, and the ability to provide uniform and precise heating.

Where can polyimide film heaters be used?

It is widely used in aerospace, medical equipment, electronic equipment, automotive industry, industrial equipment and communication equipment, etc. It is suitable for applications requiring precise temperature control and complex installation conditions.

What is the power density of polyimide film heaters?

Polyimide film heaters typically have a power density of up to 1.5W/cm², which can be customized to the application to ensure efficiency and safety.

What is the thickness of polyimide film heaters?

Typically 0.1mm to 0.3mm thick, their ultra-thin design allows them to be easily mounted on narrow or irregular surfaces without affecting the overall structure or function of the equipment.

How do I install a polyimide film heater?

Many polyimide film heaters come with a self-adhesive backing that allows them to be attached directly to the surface to be heated. Users may also choose to install them in other ways, such as by soldering the terminals or using screws to secure them.

What is the voltage range of polyimide film heaters?

Polyimide film heaters are available in a wide range of voltages, including 3.7V, 5V, 12V, 24V, 110V, and 220V, allowing the user to select the appropriate voltage range for their specific needs.

Do polyimide film heaters support customization?

Yes, polyimide film heaters support customized shapes, sizes, voltages, power densities and other parameters to meet the requirements of different equipment and application scenarios.

What is the typical service life of polyimide film heaters?

Polyimide film heaters have a long service life and can typically be used for many years under normal operating conditions, depending on the operating environment and operating temperature.

Previous: Floor Heating Film

Next: Spiral heating element

Contact

No. 1, 1st Road, Mawu Industrial Zone, Qiaoli, Changping Town, Dongguan City, Guangdong Province

Email:

Phone:

+86 136-2001-9955

+86-0769-83488762-8016