Carbon Fiber Heating Film: Technology, Applications, and Maintenance

Introduction

Carbon Fiber Heating Film (CFHF) is an advanced electric heating technology that utilizes carbon fiber as the conductive material. It converts electrical energy into thermal energy through the Joule heating effect, offering uniform heat distribution, raPId response, and high energy efficiency. This innovative solution has gained prominence in residential, industrial, and automotive applications due to its superior performance compared to traditional heating methods.

Key Characteristics of Carbon Fiber Heating Film

1. High Thermal Efficiency

CFHF achieves a thermal conversion efficiency of ≥99%, significantly higher than conventional resistive heating Elements (typically 70-85%). The carbon fiber matrix enables near-instantaneous heating, reaching operational temperatures of 50-60°C within 30-60 seconds. Energy consumption is reduced by 30-40% compared to metal-based heating systems due to lower thermal inertia.

2. Uniform Heat Distribution

The anisotropic conductivity of carbon fiber creates a temperature variance of ≤±2°C across the film surface, compared to ±5-10°C in traditional systems. This uniformity is achieved through precise fiber alignment (typically 10-12μm diameter fibers at 200-300 fibers/cm² density) and advanced encapsulation technologies.

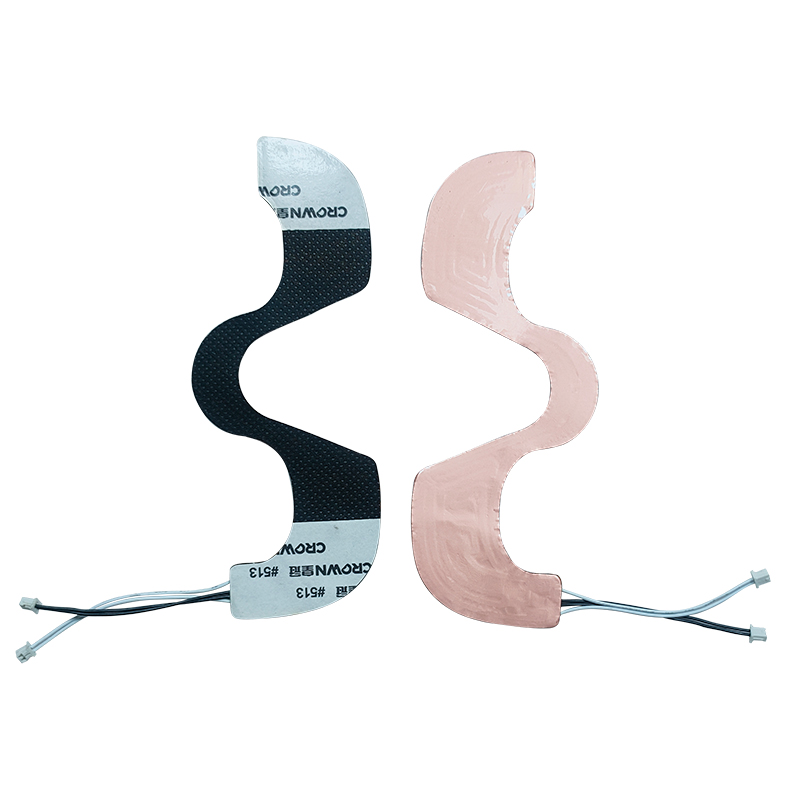

3. Mechanical Flexibility

With a thickness ranging from 0.2-1.0mm and bending radius capabilities down to 5mm, CFHF maintains functionality after 10,000+ bending cycles (ASTM D2176 standard). The tensile strength of 150-200MPa allows installation on curved surfaces without performance degradation.

4. Electromagnetic Safety

CFHF generates electromagnetic fields below 0.5μT at 30cm distance (compared to 2-5μT for conventional heaters), complying with ICNIRP 2020 guidelines. The dielectric strength exceeds 3kV/mm, ensuring safe operation in humid environments (IP67 rating achievable with proper encapsulation).

Application Scenarios

1. Residential Heating Systems

CFHF is integrated into Floor Heating Systems (30-50W/m² output), wall panels (40-60W/m²), and ceiling installations. It maintains consistent surface temperatures of 24-28°C with response times 60% faster than water-based systems. Smart thermostats enable zone control with ±0.5°C precision.

2. Automotive Applications

Used in EV battery thermal management (operating range -40°C to 85°C), seat heating (15-25W per seat), and windshield defrosting (reaching 40°C in <90 seconds). The lightweight nature (0.3kg/m² vs 1.2kg/m² for traditional systems) contributes to vehicle efficiency.

3. Industrial Processes

CFHF enables precise temperature control in composite curing (maintaining ±1°C at 80-180°C), food processing equipment, and semiconductor manufacturing. The EMI-free operation prevents interference with sensitive electronics.

4. Medical Therapeutics

In physical therapy devices, CFHF provides controlled heat penetration (2-3cm depth at 40-45°C) with automatic shutoff after 20-30 minutes. The biocompatible materials meet ISO 10993-5 cytotoxicity standards.

Maintenance Guidelines

1. Installation Considerations

Ensure surface flatness with ≤2mm/m² irregularities. Use thermally conductive adhesives with ≥1.5W/m·K conductivity. Maintain minimum 10cm clearance from flammable materials and 5cm from electrical conduits. Ground resistance should measure <0.1Ω (IEC 60364-7-710).

2. Operational Maintenance

Perform quarterly resistance checks (deviation should be <±10% from="" initial="" values="">3H pencil hardness recommended).

3. Performance Monitoring

Use infrared thermography annually to detect hotspots (>5°C variance indicates potential issues). Monitor power consumption fluctuations (>15% increase may signal degradation). Expected lifespan is 50,000+ hours at continuous 60% load.

4. Storage Conditions

Store rolls vertically in environments with 30-60% RH at 10-30°C. Avoid compression (>50kg/m²) that could damage fiber alignment. Shelf life is 5 years when vacuum-sealed with desiccant.

Technical Specifications

Power Density: 50-500W/m² (adjustable)

Surface Temperature Range: 30-150°C (standard), up to 250°C (specialized)

Thermal Response Time: <60 seconds to reach 80% of target temperature

Dielectric Withstand Voltage: ≥3000V AC for 1 minute

Insulation Resistance: ≥100MΩ at 500VDC

Fire Rating: UL94 V-0 compliant