Carbon Fiber Heating Element: Technology, Applications, and Maintenance

What is a Carbon Fiber Heating Element?

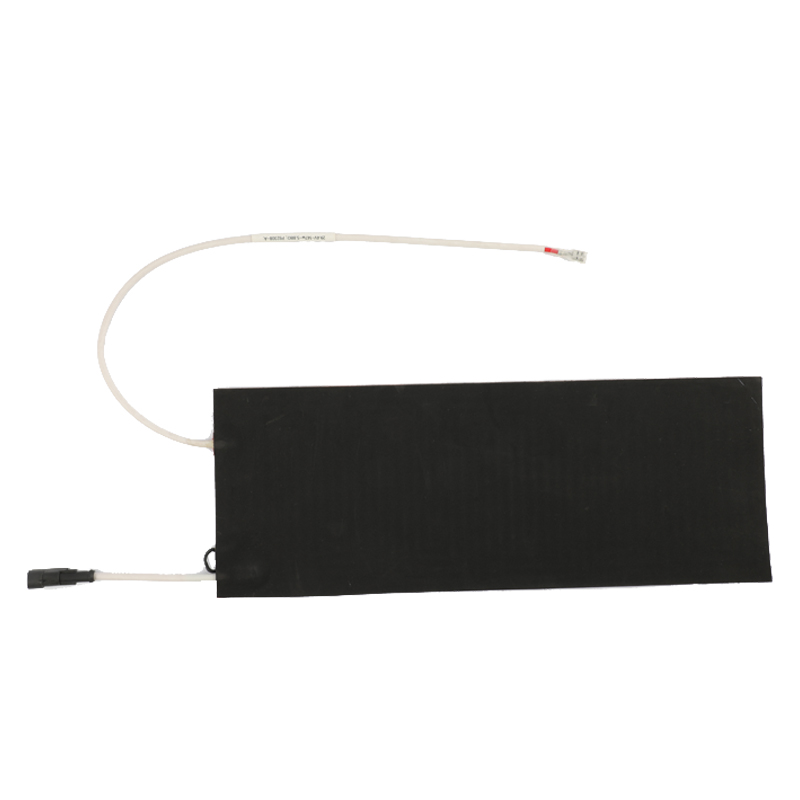

A Carbon Fiber Heating Element is an advanced thermal component that utilizes carbon fiber as its primary conductive material. Unlike traditional metal-based heating elements, carbon fiber offers superior thermal properties with a thermal conductivity of 1,000-2,000 W/m·K (compared to copper's 400 W/m·K). These elements tyPIcally operate at temperatures ranging from 30°C to 300°C, with some industrial variants capable of reaching 800°C. The carbon fibers are usually woven into fabrics or arranged in parallel strands, with thicknesses varying from 0.1mm to 5mm depending on application requirements.

Key characteristics include 98% electrothermal conversion efficiency, response times under 30 seconds to reach operating temperature, and power densities of 100-500 W/m² for standard residential applications.

Technical Characteristics

Energy Efficiency: Achieves 30-50% energy savings compared to conventional nichrome wire heaters due to the negative temperature coefficient of resistance (TCR of -0.05%/°C).

Uniform Heat Distribution: Provides temperature uniformity within ±2°C across the entire surface area, compared to ±10°C for metal coil heaters.

Mechanical Properties: Maintains structural integrity with tensile strength of 3,000-7,000 MPa and elastic modulus of 200-600 GPa while heated.

EMI Performance: Generates electromagnetic interference below 30 dBμV/m, significantly lower than metal heating elements.

Lifespan: Typical operational life exceeds 50,000 hours with proper maintenance, compared to 10,000-20,000 hours for conventional elements.

Applications

Residential Heating

Carbon fiber heating mats (typically 100-150 W/m²) are embedded in floors, walls, or ceilings. They provide 20-40% faster room heating than hydronic systems while maintaining surface temperatures below 35°C for safety.

Industrial Processes

In manufacturing, Carbon fiber heaters with 400-800 W/m² power density are used for plastic thermoforming (operating at 150-250°C), composite curing (80-180°C), and semiconductor processing (with temperature stability of ±0.5°C).

Automotive Systems

Used in EV battery thermal management (maintaining 15-35°C with 5°C uniformity), seat heating (reaching 40°C in 90 seconds), and windshield de-icing (clearing 3mm ice in 5 minutes at -20°C).

Medical Equipment

Patient warming blankets maintain 37±0.3°C with 12V DC operation. Surgical equipment uses carbon fiber heaters for precise temperature control within ±0.1°C at 50-200°C ranges.

Aerospace

De-icing systems for aircraft wings operate at 15-30 W/ft² with 200-300°C capability. Satellite components use ultra-thin (0.05mm) carbon fiber heaters with 28V DC power.

Maintenance Procedures

Cleaning

Use only neutral pH (6-8) cleaners applied with <50 psi pressure. Avoid abrasive materials that could damage the 5-20μm protective coating. For industrial applications, perform quarterly infrared thermography scans to detect hot spots exceeding 10°C above average.

Electrical Maintenance

Monthly check resistance values (typically 10-100 Ω/m²); variations beyond ±15% indicate damage. Verify insulation resistance remains above 1 MΩ at 500V DC. For high-voltage systems (>100V), perform annual dielectric strength tests at 2.5x operating voltage.

Mechanical Inspection

Check for delamination (gap detection limit 0.1mm) using ultrasonic testing. In flexible applications, verify bending radius remains above 5x element thickness. For rigid panels, monitor flatness tolerance within 1mm/m.

Performance Calibration

Annually calibrate temperature sensors to within ±0.5°C accuracy. Verify controller response time (<1 second for temperature adjustments). For PID-controlled systems, tune parameters to maintain <1°C overshoot during step changes.

Environmental Protection

In humid environments (>80% RH), apply conformal coating with >1,000Ω·cm surface resistivity. For outdoor applications, ensure UV-resistant coatings with >5,000 hours QUV testing. In corrosive atmospheres, use 316L stainless steel or titanium protective layers.