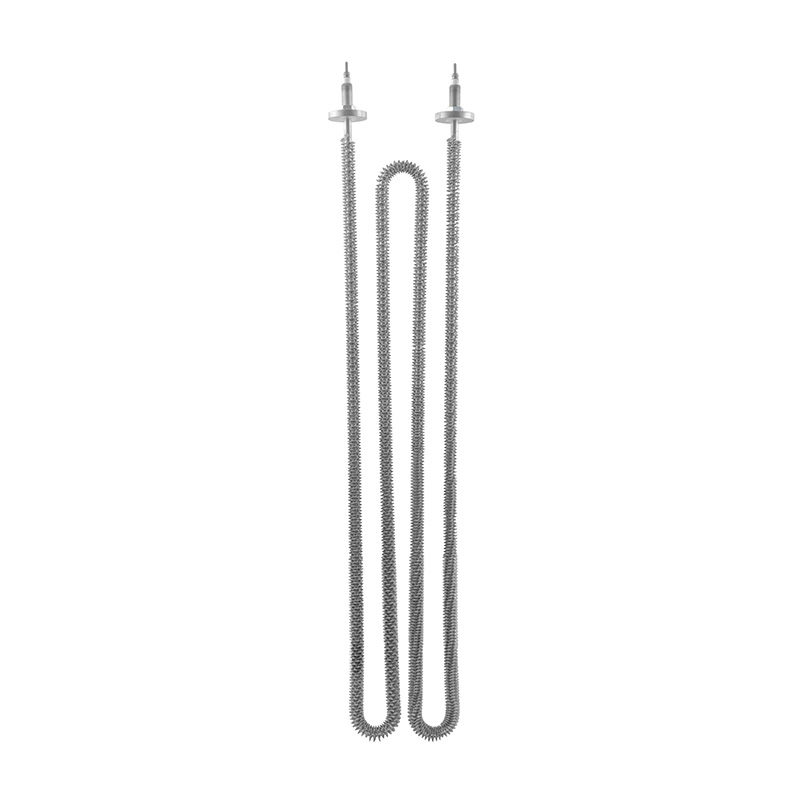

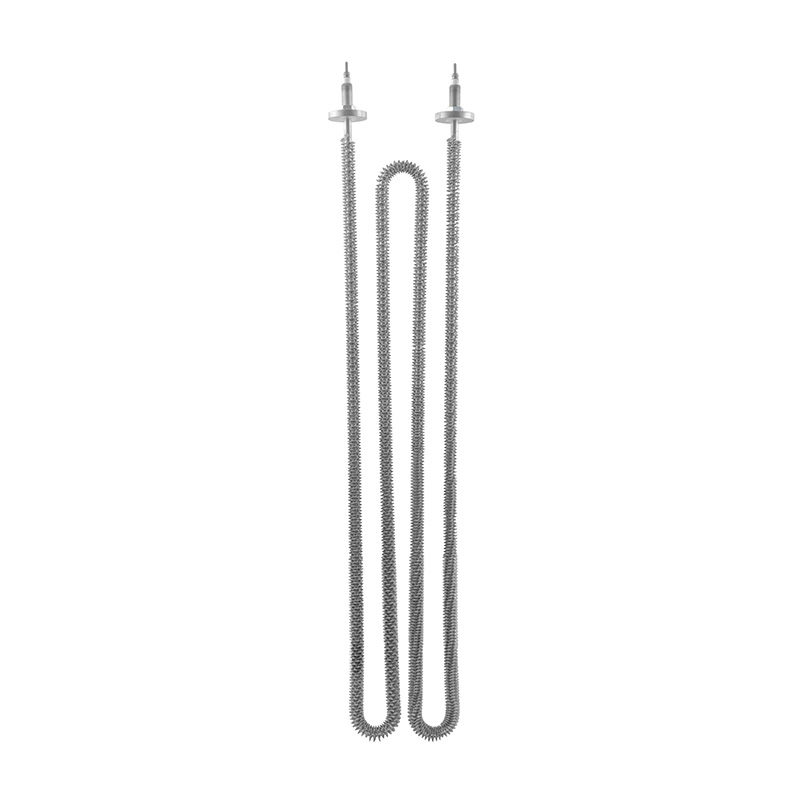

The Electric Tubular Heating Element is a highly versatile and efficient heat source widely used in both industrial and commercial heating applications. Engineered with a durable metal sheath—commonly stainless steel, Incoloy, or copper—this component transforms electrical energy into heat through a resistive coil encased in an insulated tube. It provides fast and uniform heating, making it a preferred solution across industries.

As a leading tubular heater supplier, we offer a full range of custom electric heating elements, including U-shaped, straight, and finned tubular heating elements, tailored to meet diverse performance and installation requirements.

The Electric Tubular Heating Element is a highly versatile and efficient heat source widely used in both industrial and commercial heating applications. Engineered with a durable metal sheath—commonly stainless steel, Incoloy, or copper—this component transforms electrical energy into heat through a resistive coil encased in an insulated tube. It provides fast and uniform heating, making it a preferred solution across industries.

As a leading Tubular Heater supplier, we offer a full range of custom electric heating elements, including U-shaped, straight, and finned Tubular Heating Elements, tailored to meet diverse performance and installation requirements.

High Heating Efficiency: Converts electricity into heat with minimal energy loss.

Durable Construction: Features sheathed heating elements using stainless steel or Incoloy for corrosion and oxidation resistance.

Custom Configurations Available: Options include single-end, double-end, and bendable Tubular Heaters for complex shapes and installations.

Temperature Resistance: Supports high-temperature applications up to 800°C depending on material.

Safety Compliance: Available with CE-certified and UL-approved designs for assured quality and reliability.

Fast Heat Transfer: Delivers immediate heat output for rapid response systems.

The electric tubular heating element is suitable for a broad spectrum of industries and devices, including:

HVAC Systems: Used in air duct heating and air handling units.

Water Heating Equipment: Ideal for boilers, water tanks, and immersion heaters.

Oil Heating Systems: Applied in industrial oil tanks and chemical heating applications.

Ovens & Furnaces: Trusted in electric furnaces, drying ovens, and food processing equipment.

Laboratory & Medical Devices: Provides precise heat control in compact spaces.

Replacement & OEM Use: Perfect for industrial equipment maintenance or as a custom OEM tubular heater.

| Parameter | Details |

|---|---|

| Product Name | Electric Tubular Heating Element |

| Sheath Material | Stainless Steel (SUS304 / SUS316 / Incoloy 800 / Copper) |

| Heating Wire | Nickel-Chromium (NiCr) Resistance Wire |

| Insulation Material | High Purity Magnesium Oxide (MgO) |

| Shape Options | Straight / U-Shape / W-Shape / Spiral / Custom |

| Voltage Range | 110V / 220V / 230V / 380V / Custom |

| Power Rating | 100W – 10kW (Customized) |

| Length Range | 100mm – 3000mm (Custom length supported) |

| Diameter | 6mm, 8mm, 10mm, 12mm, 14mm, 16mm, 18mm, etc. |

| Surface Load | 3 – 12 W/cm² (depends on sheath material & application) |

| Working Temperature | Max. 800°C (varies by material) |

| Connection Terminal | Threaded Stud / Lead Wire / Terminal Lug |

| Installation Type | Flange Mounted / Screw-in / Clamp / Insert Type |

| Insulation Resistance | ≥ 1000 MΩ (cold condition) |

| Leakage Current | ≤ 0.5 mA |

| Certification | CE, UL, ISO9001 |

| Customization | Shape, Voltage, Wattage, Terminal Type, Sheath Material, etc. |

Finned Tubular Heating Element for Air

Electric Immersion Heater Element for Water and Oil

Custom Shaped Tubular Heating Elements

Stainless Steel Tubular Heater with Thermostat

Industrial Heating Element with High Watt Density

Q1: What materials are available for your tubular heating elements?

A1: We provide stainless steel, Incoloy, and copper sheathed heating elements, depending on your corrosion resistance and temperature requirements.

Q2: Can I get a custom electric tubular heating element?

A2: Yes, we support OEM tubular heating element customization in size, voltage, shape, and wattage based on your application needs.

Q3: Are your products certified?

A3: Yes, our products comply with CE and UL standards, ensuring quality and safety.

Q4: What’s the typical lifespan of a tubular heater?

A4: With proper use, an electric tubular heating element can last over 10,000 hours, depending on the environment and load.

Contact

No. 1, 1st Road, Mawu Industrial Zone, Qiaoli, Changping Town, Dongguan City, Guangdong Province

Email:

Phone:

+86 136-2001-9955

+86-0769-83488762-8016