Aluminium Heat Plate is an efficient, durable and versatile thermal management solution for a wide range of industrial and electronic devices that require uniform heating and efficient heat dissipation. With its excellent thermal conductivity, light weight and strength, and customization options, Aluminium Heat Plate provides reliable thermal management and heat dissipation for a wide range of applications. Whether in electronic equipment, industrial heating equipment, home appliances or the automotive industry, Aluminium Heat Plate is an ideal choice.

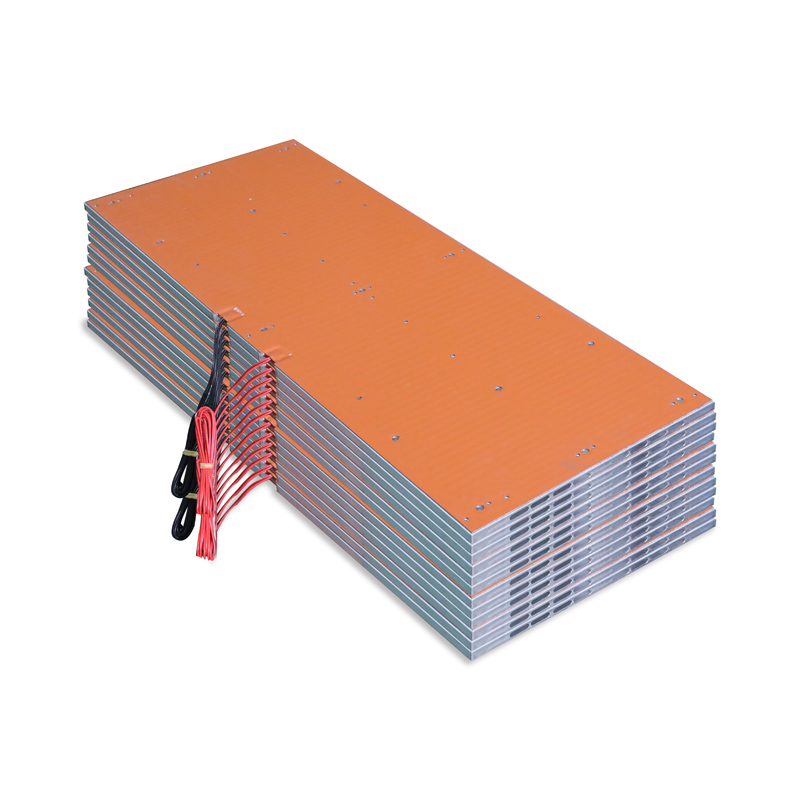

The Aluminium Heat Plate is a highly efficient and reliable component widely used in modern heating and thermal management systems. Engineered from premium-grade aluminum alloy, this product ensures rapid and uniform heat transfer across various surfaces. Whether you refer to it as an Aluminum Heating Plate, Aluminum Heat Transfer Plate, or Aluminum Heater Plate, this solution stands out for its performance, durability, and adaptability across industrial, commercial, and consumer applications.

Superior Thermal Conductivity

As an Aluminium Thermal Conductive Plate, it offers excellent heat distribution performance. With high thermal conductivity, it eliminates temperature inconsistencies and ensures even heat transfer—ideal for critical systems requiring precise thermal regulation.

Lightweight and Strong

The Aluminium Base Heat Plate is lightweight yet structurally strong. Its high strength-to-weight ratio makes it easy to install, move, or embed into complex equipment setups, while maintaining structural integrity under high temperatures and mechanical loads.

Excellent Corrosion Resistance

With a surface often treated through anodizing or passivation, this Aluminum Electric Heating Plate can resist oxidation and corrosion, significantly extending its service life, even in moisture-rich or chemically exposed environments.

Customizable and Easy to Process

The aluminum alloy body allows flexible fabrication, enabling the production of custom-sized Aluminium Heat Plates to fit specific machinery and designs. This makes it a popular choice for equipment manufacturers seeking adaptable heating solutions.

High Heat Dissipation Efficiency

As an Aluminium Radiant Heat Plate, its ability to rapidly absorb and dissipate heat helps protect heat-sensitive components and improve overall energy efficiency in thermal systems.

The Aluminium Heating Plate plays a crucial role in many applications that require stable and effective heat control:

Electronics and LED Systems

Used as an Aluminium Heating Pad Base in electronics, it prevents overheating in CPUs, GPUs, power supplies, and LED modules, prolonging device lifespan.

Industrial Heating Machinery

Ideal for injection molding machines, extruders, and other processing equipment where uniform heating is essential for maintaining product quality.

Heat Exchangers

Acts as an Aluminum Heat Transfer Plate to enhance efficiency in heat exchanger systems, transferring thermal energy between fluids or surfaces.

Automotive Components

Supports thermal management in vehicle systems such as battery packs, engine control units, and braking systems, where thermal stability is critical.

Home Appliances

Commonly found in ovens, toasters, and induction cooktops, where it serves as a stable heating element base that distributes heat evenly and rapidly.

Solar Water Heating Systems

Functions as a heat collection surface, transferring thermal energy from sunlight to water in solar applications with minimal energy loss.

Installation

The Aluminium Heat Plate can be mounted using bolts, welding, or clamps. For optimal heat conduction, ensure tight contact between the plate and the heating element or target surface.

Maintenance

Simple yet effective—keep the surface clean and periodically inspect mounting points. For long-term reliability, avoid corrosive chemicals and ensure proper ventilation around high-temperature zones.

Packaging

Each Aluminum Heater Plate is subjected to strict quality inspections and securely packaged in impact-resistant materials to ensure safe delivery.

Shipping Options

Delivered via air, sea, or express depending on your urgency and order size. Global shipping solutions ensure quick access to your thermal management components.

What is Aluminium Heat Plate?

Aluminium Heat Plate is a kind of heating plate made of aluminum alloy with excellent thermal conductivity and heat dissipation performance, used to distribute heat evenly to the heating element or equipment surface, widely used in heating and thermal management field.

What is the main material of Aluminium Heat Plate?

Aluminium Heat Plate is mainly made of aluminum alloy material (such as 6061, 5052, etc.), which has excellent thermal conductivity and corrosion resistance.

What is the maximum working temperature of Aluminium Heat Plate?

Aluminium Heat Plate is typically capable of stable operation in the temperature range of 200°C - 300°C. The exact operating temperature depends on the aluminum alloy specification. The exact operating temperature depends on the specification of the aluminum alloy and the surface treatment.

What is the typical thickness range of Aluminium Heat Plate?

Aluminium Heat Plate thicknesses typically range from 2 - 10 mm. Depending on the application, different thicknesses can be customized to suit specific heat dissipation requirements.

What are the main applications for Aluminium Heat Plate?

Aluminium Heat Plate is mainly used in electronic equipment cooling, industrial heating equipment, heat exchangers, automotive industry, household appliances and solar water heaters.

How can Aluminium Heat Plate be customized?

Aluminium Heat Plate can be customized in terms of size, shape, thickness, surface treatment (e.g. anodized, plated, painted) and accessories (e.g. fixing brackets, fixing holes for heating elements) according to customer requirements.

How to install Aluminium Heat Plate?

Aluminium Heat Plates are usually bolted, clamped or welded to the equipment. When mounting, it is necessary to ensure that the contact surface is flat for optimal heat transfer.

What are the surface treatments for Aluminium Heat Plates?

The surface treatment of Aluminium Heat Plate includes anodizing, plating, spraying, etc. These treatments can improve its corrosion resistance and aesthetics to adapt to different working environments.

What are the maintenance requirements for Aluminum Heat Plate?

Maintenance requires regular inspection of the surface of the heat plate for dust or dirt accumulation, and timely cleaning to maintain good heat dissipation performance. Also check whether the fixing parts are firm to avoid shifting or poor contact due to vibration or loosening.

How to choose the right Aluminum Heat Plate?

Selecting the right Aluminum Heat Plate requires consideration of the following factors: operating temperature, thermal conductivity, size and shape, thickness, surface finish requirements, and specific application scenarios. Based on these factors, the most appropriate type of aluminum alloy and finish should be selected to ensure that it meets the needs of the application.

Previous: Heating Wire

Next: Mica Plate Heater

Contact

No. 1, 1st Road, Mawu Industrial Zone, Qiaoli, Changping Town, Dongguan City, Guangdong Province

Email:

Phone:

+86 136-2001-9955

+86-0769-83488762-8016